Grease is a widely used lubricant that has numerous applications in various industries and everyday life. From automotive parts to kitchen machinery, greases play a vital role in reducing friction and protecting surfaces from wear and tear. However, not all greases are created equal. There are various types of greases available in the market, each with its own unique properties and applications. Understanding the differences between these types of greases is crucial in selecting the right one for specific purposes.

In this comprehensive guide, we will delve into the world of greases and explore the different types available, their compositions, and best uses. Whether you are a seasoned industrial professional or a curious consumer, this article will provide you with everything you need to know about the various types of greases, helping you make informed decisions in choosing the best lubricant for your needs. So, let’s dive in and discover the world of greases together.

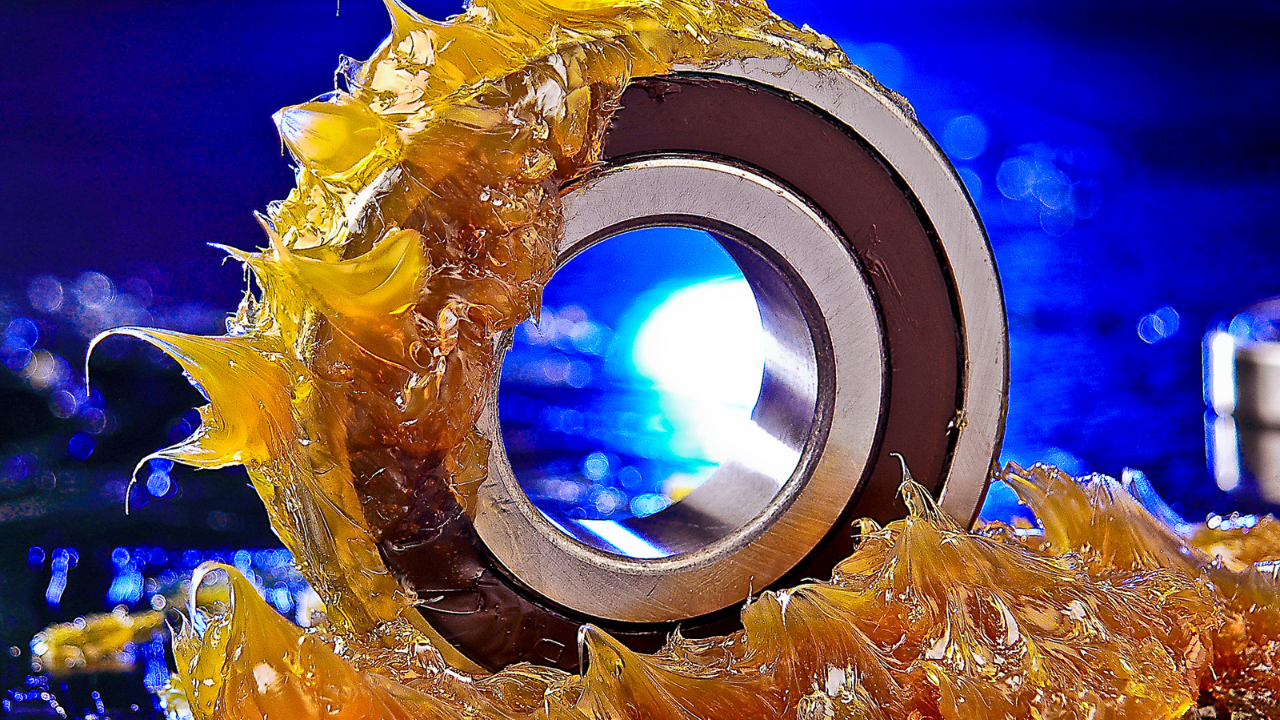

Comprehensive Guide to Bearing Grease

When it comes to ensuring the optimal performance and longevity of bearings, choosing the right type of grease is crucial. Different types of grease are specifically formulated to meet the unique requirements of various bearing applications. Before diving into the world of bearing greases, it is important to understand the key factors to consider when selecting the appropriate lubricant.

Factors such as operating temperature, load capacity, speed, and environmental conditions play a significant role in determining the ideal grease for a particular bearing application. With a wide range of options available, including lithium-based, synthetic, and high-temperature greases, it is essential to match the grease properties to the specific demands of the bearing. By carefully evaluating these factors and choosing the right grease, one can ensure smooth operation, reduce friction, prevent wear and corrosion, and extend the overall lifespan of the bearings.

Understanding Different Types of Grease

Grease is a versatile lubricant used in various industries, with different types designed for specific applications. Lithium grease, the most common type, is ideal for general-purpose use due to its water resistance and wide temperature range. For heavy-duty applications like automotive and industrial machinery, molybdenum disulfide grease provides excellent load-carrying capacity and extreme pressure protection. Silicone grease is non-reactive and works well with rubber and plastic, often used in O-rings and electrical components. White lithium grease, with added zinc oxide, is excellent for metal-to-metal applications due to its anti-corrosion properties.

Marine grease, formulated to resist water washout and corrosion, is perfect for boat trailers and equipment exposed to water. Finally, food-grade grease is essential in the food industry, formulated to be non-toxic and safe for incidental contact with food, commonly used in processing equipment. Understanding these various types of grease ensures selecting the right one for specific needs, promoting equipment longevity, efficiency, and safety across a range of industries.

Exploring the Variety of Greases Available

When it comes to exploring the variety of greases available, there is a wide range of options to choose from based on specific applications. Types of grease for bearings, for example, include lithium-based greases, which offer good water resistance and high bearing life, making them ideal for automotive and industrial applications. Calcium-based greases, on the other hand, provide excellent resistance to oxidation and are commonly used in general purpose lubrication. For high-temperature environments, silicone-based greases are often preferred due to their ability to withstand extreme heat and provide excellent dielectric properties.

Additionally, there are specialized greases such as molybdenum disulfide greases for heavy-duty applications and white lithium greases for applications requiring food-grade lubrication. Each type of grease has its own unique properties and uses, ensuring that there is a suitable option available for various lubrication needs. By understanding the different types of greases and their specific applications, you can make informed decisions when selecting the most appropriate lubricant for your requirements.

Practical Applications and Recommended Uses

Practical applications and recommended uses of different types of grease play a crucial role in ensuring optimal performance and longevity of machinery and equipment. In the case of types of grease for bearings, lithium-based greases are often recommended for automotive and industrial applications due to their excellent water resistance and ability to provide a long bearing life. Calcium-based greases, on the other hand, are widely used for general purpose lubrication, thanks to their exceptional oxidation resistance.

In high-temperature environments, silicone-based greases prove their worth by offering excellent heat resistance and electrical insulation properties. Specialised greases like molybdenum disulfide greases are ideal for heavy-duty applications, while white lithium greases are commonly chosen for applications requiring food-grade lubrication. By considering the specific requirements and conditions of each application, selecting the appropriate type of grease can significantly enhance the efficiency and reliability of machinery and equipment.

Commonly Used Greases in Automobiles

Automotive systems rely on various types of grease to ensure smooth and efficient operation. Types of grease lubricant commonly used in automobiles include lithium-based greases, calcium-based greases, and silicone-based greases. Lithium-based greases are highly versatile and provide excellent water resistance, making them suitable for applications such as wheel bearings and chassis components.

Calcium-based greases are commonly used for general purpose lubrication in automotive systems due to their superior oxidation resistance. Silicone-based greases are preferred in high-temperature environments, as they offer exceptional heat resistance and electrical insulation properties. Additionally, molybdenum disulphide greases find their application in heavy-duty scenarios, while white lithium greases are chosen for their food-grade lubrication capability. Selecting the right type of grease for specific automotive components and conditions is essential in maintaining optimal performance and extending the lifespan of the vehicle.

Conclusion

Understanding the different types of grease and their unique properties is crucial for choosing the right grease for your specific application. From the thick and sticky consistency of lithium-based grease to the high temperature resistance of silicone-based grease, each type has its own advantages and uses. By considering factors such as application, temperature, and load, you can select the most suitable grease for your equipment, ensuring optimal performance and longevity.

With this knowledge, you can confidently maintain and lubricate your machinery, keeping them running smoothly and efficiently. By the way keep our number handy for when the unexpected happens – we’re here with roadside assistance you can trust!